更多用户选择精密管

更新时间:2025-11-27 21:13:49 ip归属地:太原,天气:晴,温度:-7-7 浏览:1次

- 发布企业

- 大鼎金属材料(太原市清徐县分公司)

- 报价

- 电议

- 品牌

- 电议

- 供货总量

- 电议

- 运费

- 电议

- 关键词

- 无缝钢管

- 所在地

- 高新区新东环路路西钢材市场58号

- 联系电话

- 0527-88266222

- 手机

- 18762195566

- 联系人

- 孙经理 请说明来自商助贸易宝,优惠更多

详细介绍

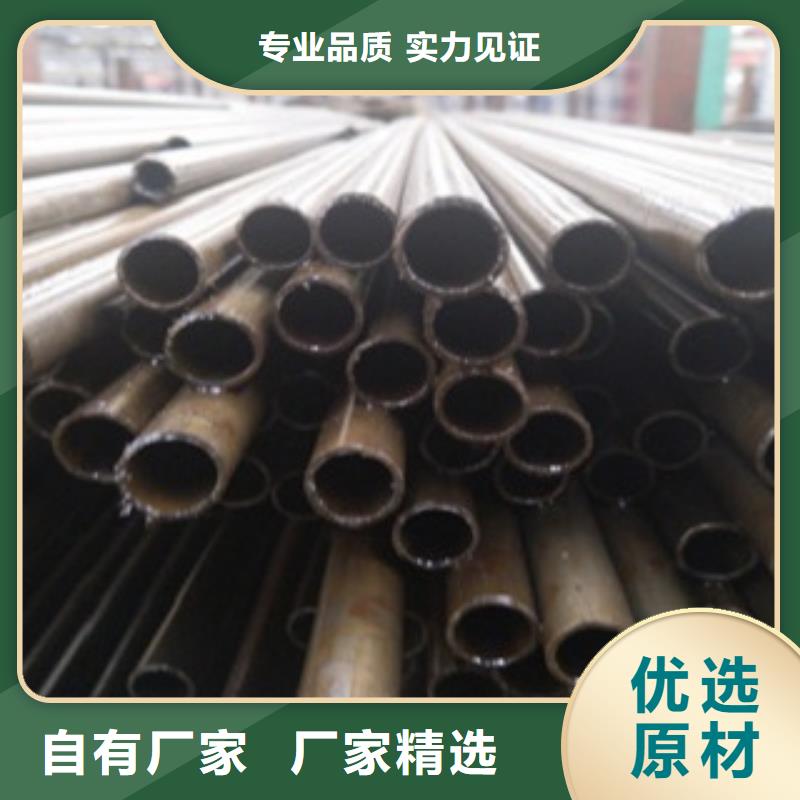

[城市太原清徐大鼎金属材料有限公司专业从事 无缝钢管的研究、销售及售后为一体的综合型企业。一直以来,公司在发展中不断完善生产管理,扩大生产规模,拥有一批高素质的专业人才及完 善的生产配套设备,公司遵循“质量立企、诚信为本、信誉至上”的经营理念,以“企业发展、员工成长”为企业文化,以“以人为本、、专业创新、客户满意”为质量方针,发扬“敬业、创新、沟通、拼搏”的企业精神,持续进行技术创新和管理创新,积j i参与国际竞争与合作,力争长期保持行业之魁 !

山东大鼎钢管厂钢管主要用于一般结构和机械结构。其代表性材料(等级):碳素钢20、45钢;合金钢Q345、20Cr、40Cr、20CrMo、30-35CrMo、42CrMo等。主要用于工程和大型设备的流体管道输送。材料(等级)为20、Q345等。GB3087.1999(20中低压力锅炉用精密钢管)。主要用于工业锅炉和家用锅炉中低压力流体的输送。材料为10钢和20钢。GB5310-1995(高压锅炉用20μm精密钢管)。主要用于电厂、核电站锅炉的高温、高压输送集流体箱和管道。材料为20g、12CR1MOVG、15CRMOG等。

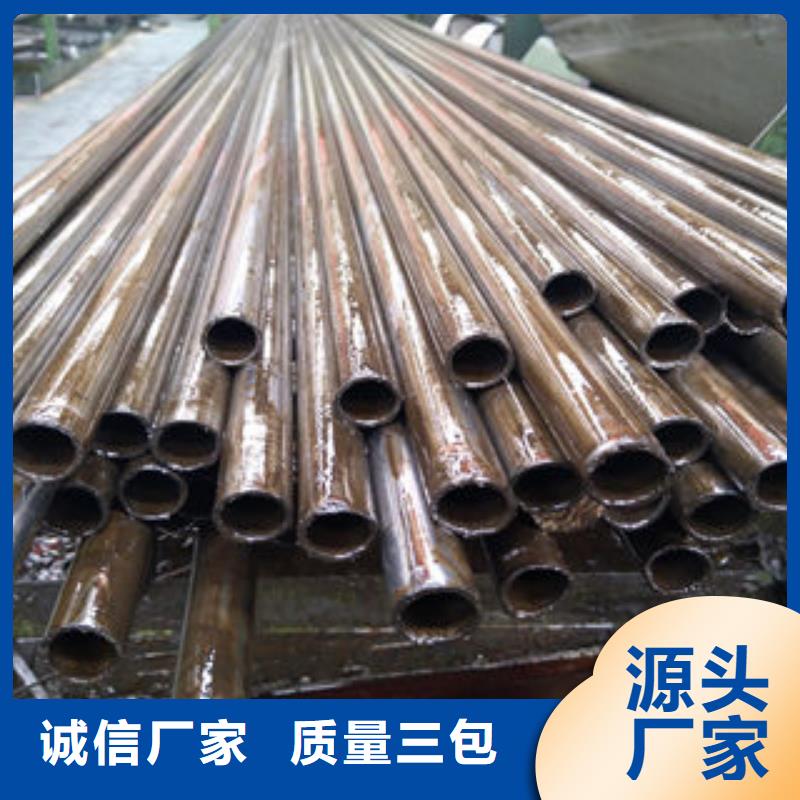

山东大鼎金属材料有限公司From a positive point of view, the market is still in weak integration. Price adjustment policies, as the weather warms, are slowly reviving the industry; if raw materials do not show too much volatility, it is difficult to fall again, because the market is less profitable and expected to be higher, so alloy tubes will be very strong after a tentative pull on the market.

Oil quenching causes surface deterioration easily. Due to the high surface activity, significant thin layer carburization can occur under the action of short and high temperature oil film. In addition, the adhesion of carbon black and oil on the surface is not conducive to simplifying the heat treatment process. The development of vacuum quenching technology mainly lies in the development of single gas cooled quenching furnace with excellent performance. Double chamber furnace can also be used for gas quenching (front chamber air jet cooling), but the operation of the two stations makes it difficult to load a large number of furnace, and easy to cause workpiece deformation or change the direction of workpiece quenching. NG deformation during high temperature movement.

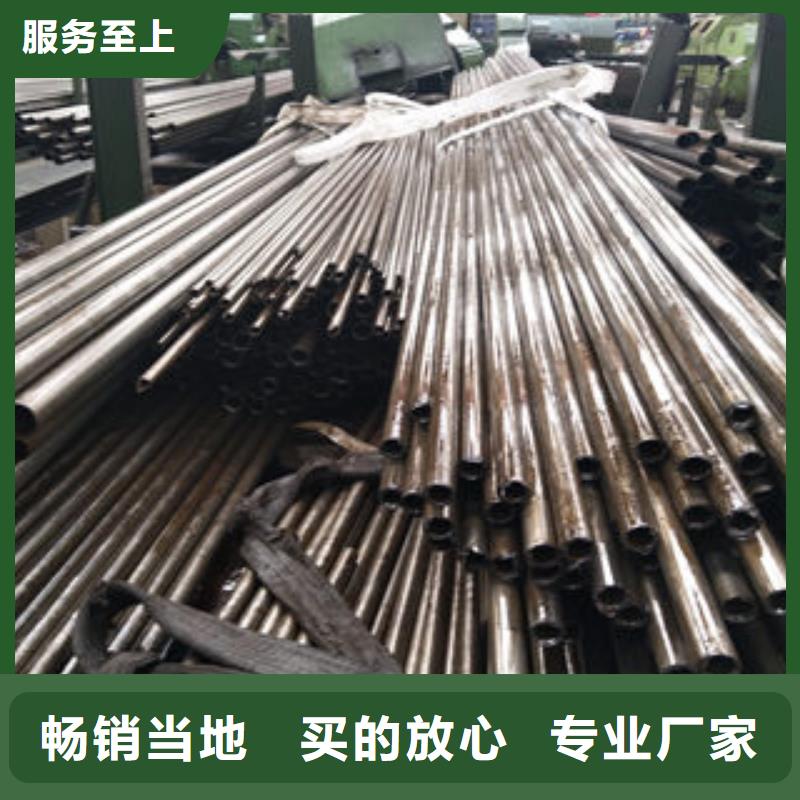

山东大鼎钢管厂公式计算钢管的理论重量:W=(D-S)*S*0.02466,其中W=钢管每米的重量;S=钢管的公称壁厚;D=钢管的公称外径,光亮管的表面质量i清洁、无氧化层、无裂纹、折叠、轧制、结疤、分离层和条纹。

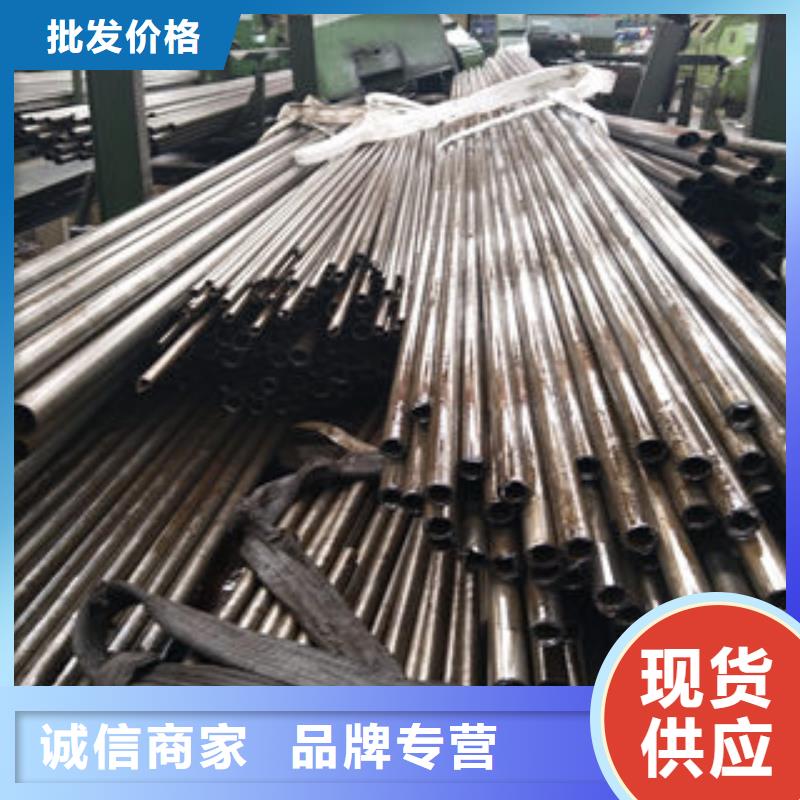

添加钛、铌等微合金元素形成弥散的氮化物或碳氮化物,导致冷轧精密光亮钢管的韧脆转变温度升高。(3)晶粒尺寸对韧脆转变温度有影响,随着晶粒粗化,韧脆转变温度升高。冷轧和精密光亮钢管的晶粒脆化倾向得到了广泛的应用。高春铁(0.01% C)的Tc在该温度以下的100C完全易碎。冷轧精密光亮钢管中大部分合金元素都提高了韧脆转变温度和冷脆倾向。室温以上发生韧性断裂时,冷轧精密光亮钢管的断口为韧窝断裂,低温脆性断裂时断口为解理断裂。

Following the decline in crude steel production in the first ten days of this month, crude steel production rose again in the first ten days of this month. Inventories of heat preservation and anticorrosion pipe manufacturers and factories also declined. The production situation of secondary or steel plants is not clear. At present, as raw material prices continue to fall, consumer enterprises still have profit margins; coupled with financial pressure, most steel mills need to maintain operation in order to continue to obtain savings; therefore, steel mills still adhere to a higher start-up rate; Anshan region, for example, as of this month, Tangshan blast high production capacity application rate. Up to.0%, the rate of increase was normal.